Introduction

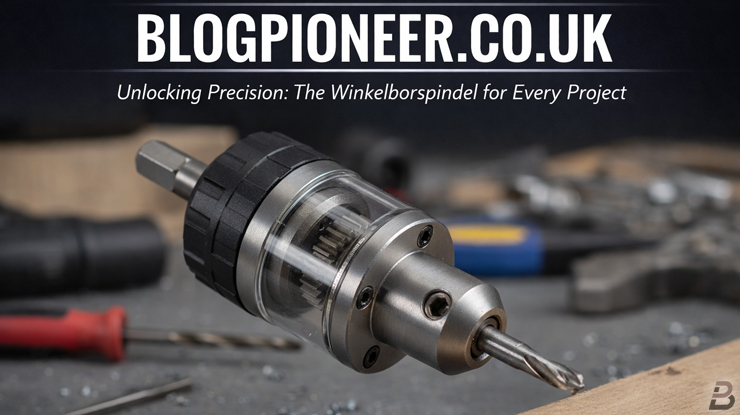

In modern machining, accuracy and flexibility are very important. Many machine parts need holes or cuts in places that are hard to reach. Sometimes, drilling straight is not possible because of the shape of the part or the limited space. This is where a Winkelbohrspindel becomes very useful.

The word Winkelbohrspindel comes from the German language. It means angle drilling spindle. This tool allows drilling or machining at an angle, usually 90 degrees, instead of straight down. It is widely used in CNC machines, metalworking, and industrial production.

This article explains what a Winkelbohrspindel is, how it works, where it is used, and why it is important in machining. The language is simple and clear so that anyone can understand it easily.

What Is a Winkelbohrspindel

A Winkelbohrspindel is a mechanical tool used to drill or machine holes at an angle. Unlike a normal spindle that works in a straight line, this spindle changes the direction of rotation. This makes it possible to work on the side of a part without turning or moving the workpiece.

Most Winkelbohrspindeln are designed to work at a right angle, but some models can work at other angles. The tool is attached to a machine spindle and transfers power through internal gears to the cutting tool.

In simple words, it helps machines reach places that are difficult to access with standard tools.

How a Winkelbohrspindel Works

The working principle of a Winkelbohrspindel is based on mechanical power transfer.

When the main machine spindle rotates, this movement goes into the Winkelbohrspindel body. Inside the tool, there are special gears, usually bevel gears. These gears change the direction of rotation from straight to angled.

The rotation then reaches the cutting tool, such as a drill or milling cutter. Because of this design, the tool can drill or cut sideways while the machine spindle stays in the same position.

This system allows precise and stable machining, even in tight spaces.

Main Parts of a Winkelbohrspindel

A Winkelbohrspindel has several important parts that work together:

Spindle Housing

This is the outer body of the tool. It protects the internal parts and keeps everything stable during operation.

Gear System

The gears inside change the direction of rotation. High quality gears are important for smooth and accurate movement.

Bearings

Bearings support the rotating parts. They reduce friction and help the spindle work at high speeds.

Tool Holder

This part holds the drill or cutting tool. It must be strong and precise to keep the tool in the correct position.

Cooling and Lubrication System

Some Winkelbohrspindeln have internal cooling. This helps reduce heat and increases tool life.

Types of Winkelbohrspindel

There are different types of Winkelbohrspindeln, designed for different tasks.

Fixed Angle Winkelbohrspindel

This is the most common type. It usually works at a 90 degree angle and is very stable and precise.

Adjustable Angle Winkelbohrspindel

This type allows changing the angle. It is more flexible but often more complex.

High Speed Winkelbohrspindel

Designed for fast drilling and light machining. It is used when speed is more important than torque.

Heavy Duty Winkelbohrspindel

This type is made for high torque and hard materials. It is stronger and often larger.

Materials That Can Be Machined

A Winkelbohrspindel can be used on many materials, depending on the tool and machine setup.

Common materials include:

- Steel

- Aluminum

- Cast iron

- Stainless steel

- Plastics

- Wood

The right cutting tool and speed must be chosen for each material to get good results.

Applications in Machining

Winkelbohrspindeln are used in many industries.

CNC Machining

In CNC machines, they allow side drilling and milling without changing the part position. This saves time and improves accuracy.

Automotive Industry

Many car parts need angled holes and complex shapes. Winkelbohrspindeln help produce these parts efficiently.

Aerospace Industry

Aircraft parts often have strict quality requirements. Angle drilling tools help reach difficult areas with high precision.

Tool and Mold Making

Molds often have deep and side holes. Using a Winkelbohrspindel makes this work easier.

Maintenance and Repair

They are also useful for repair work where access is limited.

Advantages of Using a Winkelbohrspindel

Using a Winkelbohrspindel offers many benefits.

Better Access

It allows machining in tight and hard to reach spaces.

Time Saving

There is no need to reposition the workpiece many times.

Higher Accuracy

Fewer setup changes reduce errors.

Increased Productivity

Machines can perform more operations in one setup.

Flexibility

Different tools can be used for drilling, milling, or tapping.

Limitations to Consider

While very useful, Winkelbohrspindeln also have some limitations.

- They can be expensive compared to standard tools

- Maintenance is important because of the internal gears

- Incorrect setup can cause vibration

- Not all machines are compatible

Proper selection and setup are important to avoid these problems.

Choosing the Right Winkelbohrspindel

When selecting a Winkelbohrspindel, several factors should be considered.

Machine Compatibility

The spindle must fit the machine and tool holder.

Speed and Torque

Choose according to the material and operation.

Angle Requirement

Decide if a fixed or adjustable angle is needed.

Tool Size

The spindle must support the required tool diameter.

Quality and Precision

High quality spindles last longer and give better results.

Maintenance and Care

Good maintenance increases the life of a Winkelbohrspindel.

- Keep it clean after use

- Check lubrication regularly

- Avoid overload and wrong speeds

- Inspect gears and bearings

- Store it in a dry and safe place

Regular care helps avoid breakdowns and keeps performance stable.

Safety Tips

Safety is very important when using machining tools.

- Always follow machine instructions

- Use proper speed and feed

- Make sure the tool is fixed tightly

- Wear safety glasses

- Stop the machine if unusual noise appears

Safe operation protects both the operator and the machine.

Future of Winkelbohrspindeln

As machining technology improves, Winkelbohrspindeln also continue to develop. New designs focus on higher precision, lighter weight, and better cooling systems. With the growth of CNC automation, these tools will remain important in modern manufacturing.

Conclusion

A Winkelbohrspindel is an important tool in modern machining. It allows angled drilling and machining in places that are hard to reach. By saving time, improving accuracy, and increasing flexibility, it helps many industries work more efficiently.

With the right selection, proper maintenance, and safe use, a Winkelbohrspindel can be a valuable addition to any machining setup. Its role in CNC machining and industrial production makes it a key tool for today and the future.

Frequently Asked Questions

1. What is the main purpose of a Winkelbohrspindel

Its main purpose is to drill or machine at an angle, usually where straight drilling is not possible.

2. Is a Winkelbohrspindel only used in CNC machines

No, it can be used in both CNC and manual machines.

3. What angle does a Winkelbohrspindel usually have

Most models work at a 90 degree angle.

4. Can it be used for milling

Yes, many Winkelbohrspindeln are suitable for light milling operations.

5. Is it difficult to install

Installation depends on the machine, but most are designed for easy mounting.

6. Does it need special maintenance

It needs regular lubrication and inspection, but no special tools are required.

7. Can it work at high speeds

Yes, some models are designed for high speed machining.

8. Is it suitable for heavy materials

Heavy duty models are suitable for hard and strong materials.

9. How long does a Winkelbohrspindel last

With proper care, it can last many years.

10. Is it worth the investment

Yes, especially for jobs that need angled machining and high precision.

READ MORE : Bill Melugin Salary: How Much Does the Fox News Reporter Earn?

Connect with us for more information : Blog Pioneer